Flat Material Setup

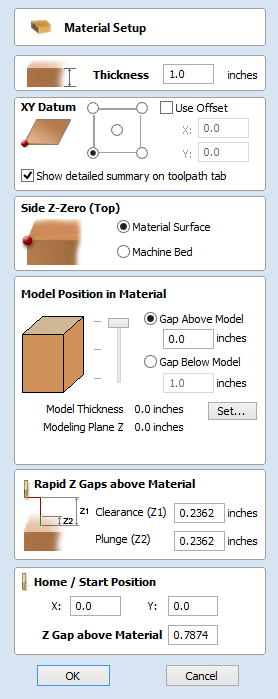

Thickness

Enter the thickness of the material being machined.

XY Datum

This allows you to set the X and Y origin of the job. See the section in Job Setup form

Show detailed summary on toolpath tab

This checkbox toggles the Material Setup summary layout on the Toolpaths tab between simple and detailed views.

Side Z-Zero

Select relative to the Material Surface or relative to the Machine Bed. This is a very important setting because the tooling used on the CNC machine must be setup in the same way, ensuring the toolpaths cut to the correct depth.

If you are working in a 2 Sided job, this will set the Z Zero for your current side only,

- The side you are setting up will be displayed in brackets e.g. (Top).

- You can set the Z-Zero for both sides through the Job Setup form.

Rapid Z Gaps above Material

Clearance (Z1)

This is the height above the job at which it is safe for the cutter to move at rapid or maximum feed rate. The software will raise the bottom of the cutter to this height when it traverses the material.

Plunge (Z2)

For all toolpaths, as well as specifying a rapid clearance gap for rapid positioning moves above the workpiece, the user can also specify a much smaller gap that the tool will rapid down to during plunge moves. By default the plunge gap is set to the same value as the Clearance gap which means that there will be no rapid plunges. If you set the plunge gap to a smaller value than the Clearance gap, the tool will plunge at rapid feed rate to the specified distance above the material surface before changing to the specified plunge rate. For jobs where a large value for Clearance gap has to be specified to avoid clamps etc, this feature can save a considerable amount of machining time if there are a lot of plunge moves in the job.

Home / Start Position

This is the absolute position that the tool will start moving from and where the tool can be programmed to return to at the end of cutting the job.